Blog: The Million Dollar Case Study Session #22: Amazon Inventory Management

The Million Dollar Case Study Session #22: Amazon Inventory Management

Predict the unpredictable. This is the impossible task that Amazon sellers, and frankly retailers since the beginning of time, have had to do to maximize their potential profits. However, if you are an Amazon seller and find yourself with a dreaded Out Of Stock note on your product detail page, the consequences are costly, and painful: a plummeting Best Seller Rank, evaporating organic sales, and most importantly, lost profits.

The solution to this challenge lies in inventory management. And there is no better person to learn the topic from than Jeremy Biron, Founder of Forecast.ly, and an Amazon seller for the better part of a decade. In this session, Jeremy takes us deep into the topic of inventory management, to learn how to forecast demand, management inventory, and maintain a healthy cash flow.

Here is a full recap of the webinar:

And here are the slides for reference:

The crux of good inventory management is that it helps you manage cash flow effectively. With an Amazon business, a lot of capital can be tied up in the beginning, as you invest in purchasing inventory to sell. Proper inventory management allows you to find that balance of stocking the right amount of inventory without tying up an excessive amount of capital in inventory that sits in an Amazon warehouse. Ultimately, if you are able to pair a profitable product with good inventory management, then you can create a well-oiled cash machine primed for growth. Now that sounds quite appealing!

Jeremy lays out the formula for effective demand forecasting and inventory management by figuring out a few key figures.

Let’s go through this one at a time, using Jungle Snugs as an example, to figure out when these should be reordered, and how many should be ordered.

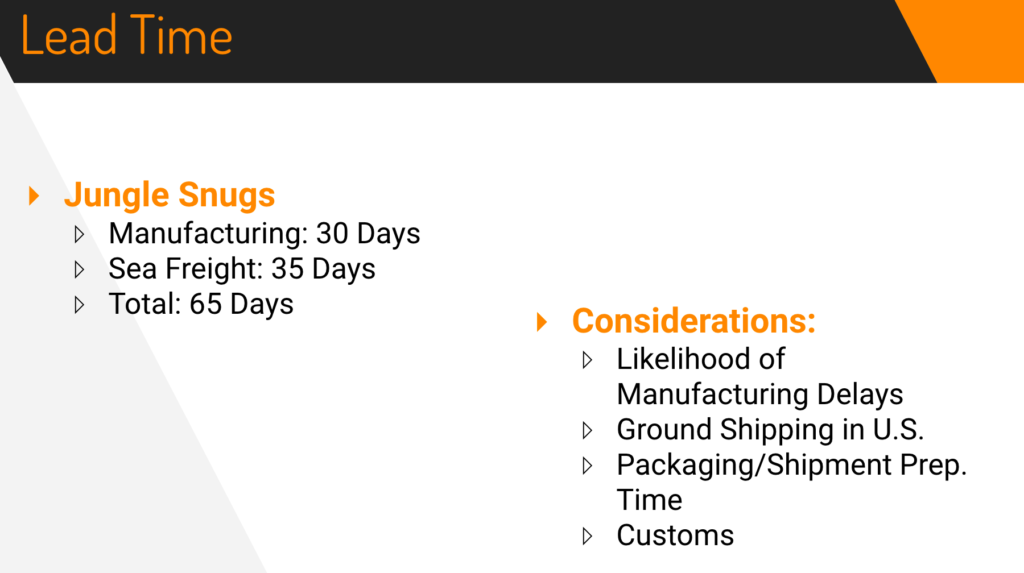

Question #1: What Is The Lead Time?

Lead time is simply the number of days required from placing an order with your supplier to having it ready for sale on Amazon.

There are a variety of steps that need to be considered (you can go through the overview page of the Million Dollar Case Study to see each of these in detail), but these considerations include: manufacturing time, packaging, shipping time, customs and importing, domestic shipping to Amazon’s warehouses, etc.

When calculating your lead time, it is crucial to be honest with your assessment, as a miscalculation here can have ramifications in subsequent calculations.

For Jungle Snugs, the Lead Time is as follows:

There are some implicit considerations here, such as: How reliable is the manufacturer? Is there likely to be a delay in manufacturing, packaging, getting it to port, etc? Is it likely that there is a delay with customs or paperwork about importing the product? All of these can impact what the lead time is.

Question #2: What Is Your Safety Stock?

Safety Stock, or “Buffer”, is your insurance inventory against a stock out. Basically, it is the extra inventory that you are willing to hold to avoid missing out on lost sales in the case of a surge in demand.

When calculating your safety stock, you need to ask yourself whether you are willing to invest more cash in inventory to avoid missing out on future sales. Again, assessing this Safety Stock figure is a ultimately just a best-guess, as you are predicting the unpredictable.

One suggestion that Jeremy offers is to not overinvest in safety stock, as tying up too much capital in idle inventory can undermine sales that you could have made elsewhere by selling a different product.

You can calculate your Safety Stock by using either days, or a percentage of your total inventory. For Jungle Snugs, we used 25% as Safety Stock.

There are two factors complicating this estimate for Jungle Snugs:

- Jungle Snugs has a long lead time, as the product ships by sea so it is harder to get a quick turnaround and restock inventory. That is one consideration when having a higher Safety Stock.

- As it is a relatively new product, there is limited sales history, so it is hard to predict how sales will proceed. Thus erring on the side of caution, the Jungle Snugs will have a roughly 25% Safety Stock.

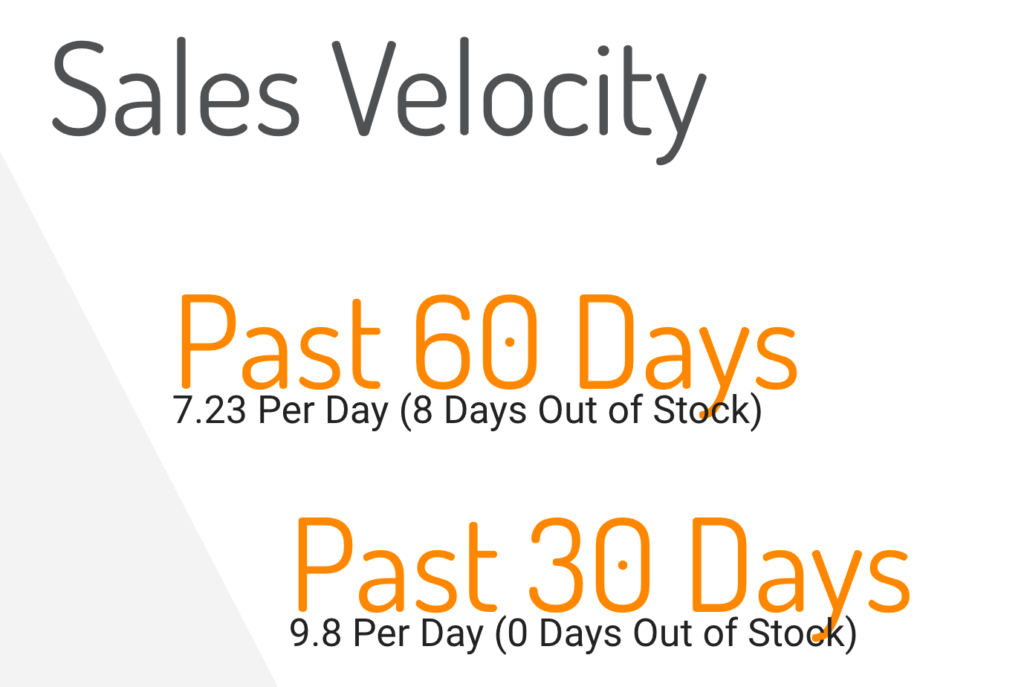

Question #3: What Is Your Sales Velocity?

Sales velocity is simply how fast you sell your inventory. How many units per day/week/month/year etc do you sell?

This is the sales velocity calculation for Jungle Snugs:

Question #4: What Is Your Current Inventory?

Take a look in Seller Central to see how much inventory you have left. Jungle Snugs currently has 537 units in stock.

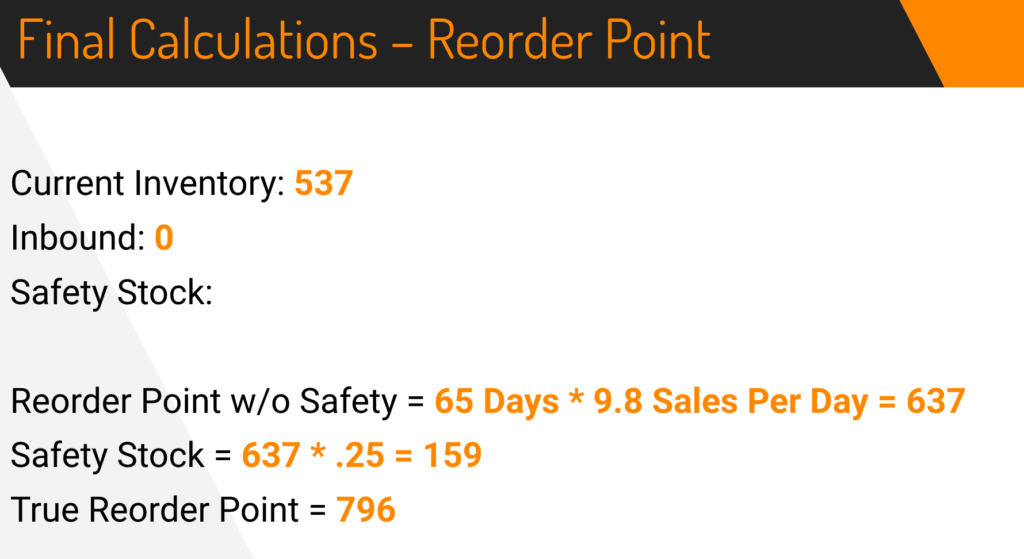

Question #5: What Is Your Reorder Point (in number of units)?

Your reorder point is basically assessing when you should reorder, based on how many units of inventory you have in stock.

Here's the calculation for the reorder point:

The calculation above takes into account how long it takes to get inventory (aka your Lead Time), and how fast you are selling units (aka your Sales Velocity).

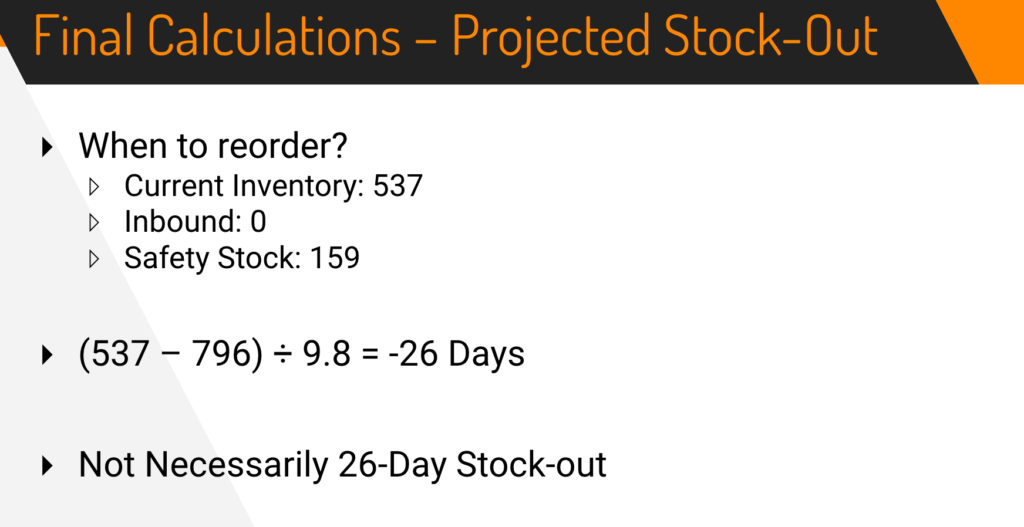

So when should we have reordered Jungle Snugs? Jeremy advises that when you place your order is actually more important than how much you order when managing your inventory.

We have 537 units in stock, plus we would want an additional 159 units (the safety stock). We are selling almost 10 per day (our 9.8 sales velocity). At this rate, we should have ordered 26 days ago, knowing that we calculated 65 days to have inventory ready for sale.

Alright then, time to order more units, STAT!

Question #5: How much should we order?

This seems like the kicker—the most important question to answer. How many units do you order?

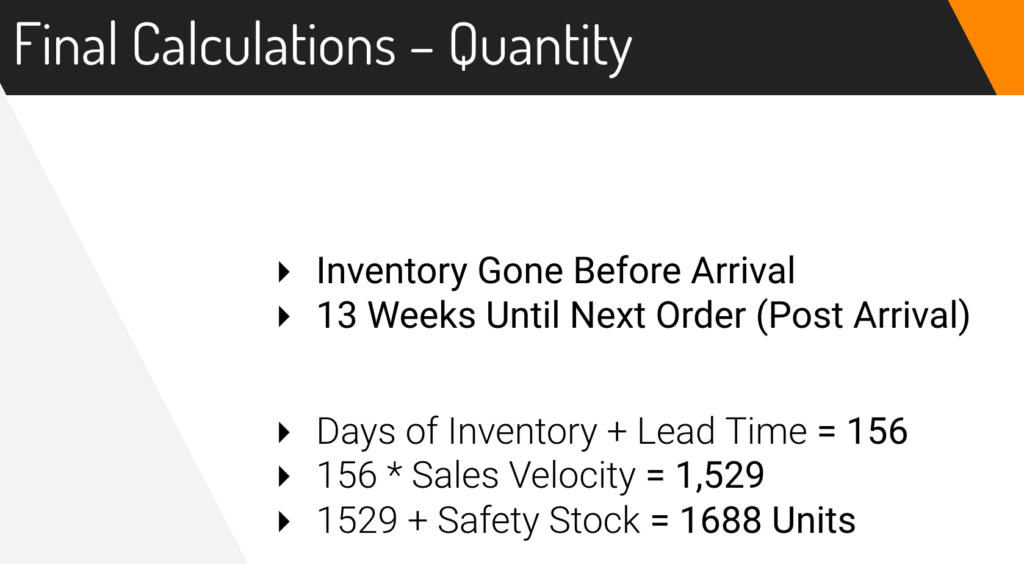

Basically just figure out how many days of inventory you have in stock, and how long it takes you to get inventory after you place an order, and convert that into actual units of inventory. This is the quantity calculation for Jungle Snugs:

Including the safety stock, we will need to order 1688 units. But don’t forget to round to the even case quantities, which will differ depending on your particular product.

Additional Tips For Savvy Inventory Management

Here are some other things to think about to be more prudent with inventory management:

- Return on Investment – how many units are you investing in, and how much will you make on that in return? What is the Return On Investment on your product? Jeremy reminds us to not think about profit in absolute terms, but as a percentage of your investment. It would be awesome to make $1000, but did you have to invest $20,000 to make that, or $1,000. Clearly you want to maximize your return on investment as much as possible!

- Import Via Ocean or Air – Importing by sea or air is a constant question for sellers. Do you wish to get the speed and flexibility of air, or the cost-savings of ocean freight? It depends on your needs at a given time, as each has its pros and cons.

- Product Segmentation – once you’ve been selling a lot, it’s important to have safety stock for your best selling products. Use a higher multiplier for your Safety Stock to ensure that you have your best selling products on hand for your. Definitely focus on your best sellers with inventory management.

- Plan Ahead – Think about your next order, not just today’s order. Pick suppliers that are good communicators, so you can be able to understand what your lead time will be, as it can be often changing.

- Know Your Assumptions – Your calculations for inventory management rely on solid assumptions. Your lead time, sales velocity, safety stock, etc. All of this can effect your decision on how much inventory to keep, and therefore what your cash flow, growth rate, and profits can look like.

A Final Gift

Jeremy put together some spreadsheets to help make the inventory management calculations easier. These spreadsheets can help you figure out each of the calculations we examined above.

You can download the sheets AT THIS LINK.

Thanks to Jeremy for an actionable and important session on inventory management. Understanding these concepts can have significant impacts on how our Amazon product fares, as inventory management is a key lever in maximizing cash flow and profits.

Next Up

Have you heard the news yet? We are moving over to part 2 of the Million Dollar Case Study… and we're going to Europe.

Join us, we're going to cover the full and unfiltered process for finding and launching a profitable product in Europe, and all of the business tasks that go with selling in a brand new marketplace. You're not going to want to miss this one.